Drilling the Enclosure

- Intro to DIY Pedal Building

- Beginner’s Course in Sketchup, Modeling a 125B Guitar Pedal Enclosure

- Drilling a 125B Guitar Effects Pedal Enclosure

- Pedal Enclosure Finishing: Surface Prep, Priming and Painting

- Using GIMP to Create Pedal Artwork

- Printing and Applying Waterslide Decal to Pedal Enclosure

Now that we’ve modeled the enclosure and printed a drilling template, we’re ready to jump out of Sketchup and into the real world.

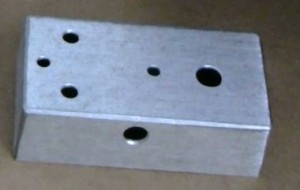

In this video, I’ll be demonstrating how to accurately drill the holes in a diecast aluminum 125B guitar pedal enclosure, preparing to install the electronics. I’m using the drilling template we printed in part 2. The pedal I’m building is a modified Ross compressor, using a printed circuit board purchased from GuitarPCB.

Funny, I just noticed while reviewing the final video edit that I was saying “barrel” instead of “bezel” for the LED bezel. I guess I was channeling my inner Cooper.

Some of the resources used in this video:

- Carl Professional Rotary Trimmer

- Automatic punch

- 3/32” drill bit- always handy. Buy a cheap 10-pack in case you break one.

- Unibit stepped drill bit. I’ve since purchased this unbelievably cheap set from Harbor Freight which has steps down to 1/8”

- Round file

- Fractional calipers – one of my favorite tools

- Weller WES51 soldering station

- Pot back covers – or just make your own with heat shrink, or electrical tape

- See more pedal-building resources in the Intro to DIY Pedal Building

September 7, 2012 @ 9:04 pm

September 7, 2012 @ 9:12 pm

September 7, 2012 @ 9:22 pm

September 7, 2012 @ 10:26 pm

September 8, 2012 @ 10:25 am

December 25, 2012 @ 3:13 pm

September 7, 2012 @ 10:39 pm

September 8, 2012 @ 10:27 am

September 8, 2012 @ 3:26 pm

September 8, 2012 @ 5:53 am

Finishing the Enclosure -

September 28, 2012 @ 6:06 pm

[…] previous posts, we modeled the enclosure in Sketchup, drilled it, and now we’re ready for paint and artwork. In this video, I talk about options for […]

Using GIMP to Create Pedal Artwork -

October 15, 2012 @ 10:09 pm

[…] next step in finishing up the pedal that we’ve modeled, drilled and painted previously, is to prepare the artwork and […]

Waterslide Decals -

December 17, 2012 @ 12:23 pm

[…] the pedal, and apply a durable clear finish. In previous videos, I showed how to model, drill, and paint the enclosure, and design and prepare the artwork and labels in […]

April 17, 2013 @ 5:57 pm

June 6, 2013 @ 11:43 am

any suggestions?

June 6, 2013 @ 3:11 pm

Better idea- use round DC jacks 🙂

July 28, 2013 @ 2:30 pm

September 3, 2013 @ 2:20 pm

January 2, 2014 @ 8:43 am

stores for busted pedals. I advertise for busted pedals in any condition. I

rarely pay more than $10. I get an enclosure and spare parts to boot.

Special switches, jacks, controls, 9v clips, caps, resistors for other

projects. A lot of times I buy a pedal that is easily repaired. It saves a

lot of time & money.

January 11, 2014 @ 5:20 pm

March 10, 2014 @ 12:11 pm

upgrade 🙂

March 29, 2014 @ 3:16 pm

June 6, 2014 @ 9:28 am

HSS drill bits and a 500W with 3000rpm drill. Do I need to buy better

drills?

July 19, 2014 @ 9:03 am

good finish 🙂

December 12, 2014 @ 10:13 am

January 11, 2015 @ 6:37 pm

January 12, 2015 @ 5:12 am

kills the vacume?!?

March 9, 2015 @ 5:23 pm

July 7, 2015 @ 1:59 pm

November 30, 2015 @ 9:07 am

Hi Jonh, amazing page. Do you have the layout of the 3PDT PCB you used ? I’ve been trying to look for a good one.

November 30, 2015 @ 9:54 am

I used an earlier version of this 3PDT board from guitarpcb:

http://www.guitarpcb.com/apps/webstore/products/show/3436229

-John

November 30, 2015 @ 10:23 am

Oh, i thought it was a DIY version, thanks for the quick response i really appreciate.

Intro to DIY Pedal Building - Planet Z

September 1, 2016 @ 11:00 am

[…] Drilling a 125B Guitar Effects Pedal Enclosure […]

Sketch Me Up! - Planet Z

September 1, 2016 @ 11:01 am

[…] Drilling a 125B Guitar Effects Pedal Enclosure […]

Finishing the Enclosure - Planet Z

September 1, 2016 @ 11:06 am

[…] previous posts, we modeled the enclosure in Sketchup, drilled it, and now we’re ready for paint and artwork. In this video, I talk about options for finishing […]

DIY Guitar Pedal Building Series - Planet Z

September 1, 2016 @ 11:49 am

[…] Drilling a 125B Guitar Effects Pedal Enclosure […]